Yes, the export will be carried out under the name of the producing company, Golshad, and according to the tax laws of the producing country, it will be exempt from paying taxes and duties (9 percent).

Yes, product samples are made upon customer’s request after registration of the request. 500g and 2kg samples will be free. In case of further demand, a sample will be sent according to the agreement.

Super-refined corn starch: 25 kg bags and 500 and 1000 kg jumbo bags

Maltodextrin: 25 kg bags

Sugar syrups: in the form of 25, 50 and 300 kg drums and 26 ton tankers

All livestock, poultry and aquatic inputs: 25 kg bags, only powdered gluten feed is available in bulk.

The best answer for this question is to refer to our customers and ask them. Golshehd has always planned the continuity of quality and timely delivery of goods by implementing quality standards and ISOs, GMP and 5S in the work environment.

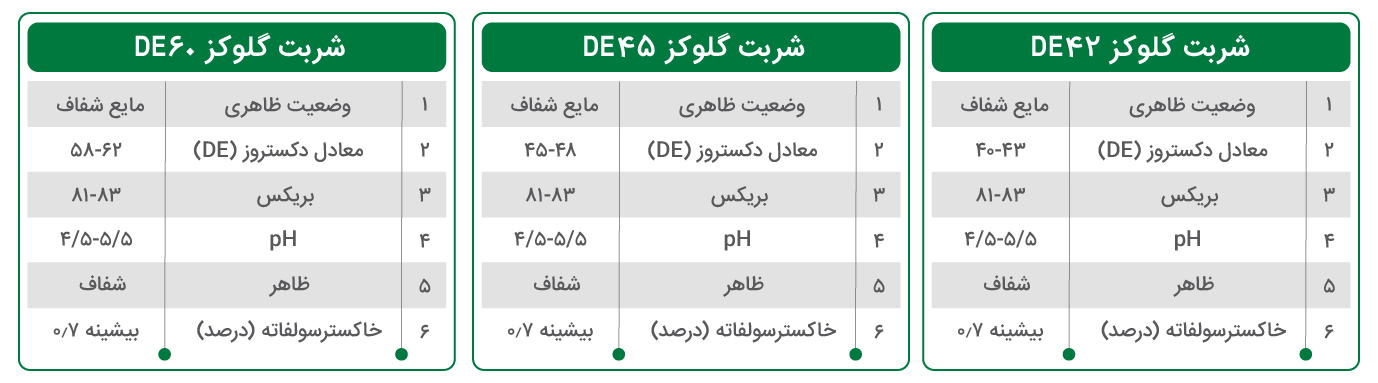

Dextrose equivalent is the percentage of reducing sugars in syrup based on dry weight, which is calculated as dextrose. DE is the word that is generally used to classify glucose syrups.

It is used to describe the carbohydrate composition of a glucose syrup in the glucose industry and shows the number of glucose units in a unique composition of the syrup.

The best answer for this question is to refer to our customers and ask them. Golshehd has always planned the continuity of quality and timely delivery of goods by implementing quality standards and ISOs, GMP and 5S in the work environment.

Dextrose equivalent is the percentage of reducing sugars in syrup based on dry weight, which is calculated as dextrose. DE is the word that is generally used to classify glucose syrups.

It is used to describe the carbohydrate composition of a glucose syrup in the glucose industry and shows the number of glucose units in a unique composition of the syrup.

Dent corn is the most common type of grain and fodder corn in the world, and during the drying of the grain, the soft starch in the upper part of the grain shrinks and creates a depression in the middle of the grain, which makes the corn grain look like a tooth, and for this reason This type of corn is called horse tooth. The part of the endosperm around the seed is horny and hard, and the middle endosperm of the seed is soft and floury. The color of the seeds varies from white to yellow. In terms of yield per unit area, it has the highest yield compared to other types of corn, and due to its great talent in grain production, corn has been called the “king of grains”.

Wet milling: It is a complex process with different operating units that are interdependent between the stages of the process, and it is a process along with water recovery, and it starts with the corn kernel steeping process.

The efficiency of starch production from corn based on dry matter is more than 66% and more than 85% of the starch produced in the world is made from corn.

Summary of starch production process:

1) Cleaning and cleaning corn seeds 2) Soaking corn seeds 3) Multi-stage mills 4) Separating the germ and dehydrating it and drying it 5) Separating the corn husk and dehydrating it and drying it 6) Separating gluten from starch by separators and dewatering and drying it 7) Complete purification of starch, dewatering and drying

Maltodextrin, glucose, maltose, dextrose sugar syrups are prepared from enzymatic hydrolysis of corn starch and have different properties depending on the degree of hydrolysis (DE equivalent).

Summary of sugar syrup production process:

1) liquefaction and conversion of starch into syrup under the effect of enzymes 2) process of saccharification 3) process of separation of impurities and coloring 4) process of purification of syrup by ion exchange columns 5) process of concentration

It is 100% enzymatic. The process of enzymatic hydrolysis of starch is much more effective in comparison with acid hydrolysis, and the product produced by this method has more favorable characteristics based on the type of enzyme used and its specific function. In addition, less undesirable substances are produced during the hydrolysis process. Also, there is no need to remove unwanted salts (resulting from acid neutralization by acid hydrolysis method). In addition, the enzymatic hydrolysis process is performed in a wider range of pH and at lower temperatures than the acid hydrolysis method. Economically, it is affordable and has higher efficiency, consumes less energy and is easier to control.

Yes, in line with the social mission and improving all processes and increasing productivity, Golshad is ready to receive research proposals related to this industry in the fields of production, quality, management, information technology, sales and marketing, research and development.