History :

Maltose was first isolated in 1819 by Saussure from the enzymatic reaction with malt diastase. Maltose was discovered by Augustine-Pierre Dubrunfaut, but the discovery was not widely acknowledged until 1872 by the Irish chemist and brewer Cornelius O’Sullivan. The word “maltose” comes from the English word “malt” combined with the suffix “-ose” which is used in the names of sugars and other carbohydrates.

Structure and naming :

Carbohydrates are usually divided into monosaccharides, oligosaccharides, and polysaccharides, depending on the number of sugar subunits they contain. Maltose with the molecular formula (C12H22O11) with a molecular weight of 342.3 Daltons, with two sugar units, is considered a disaccharide because it consists of two glucose molecules. Glucose is a hexose: a monosaccharide with six carbon atoms. The two glucose units are in the form of pyranose and the first carbon (C1) of the first glucose is linked to the fourth carbon (C4) of the second glucose by a glycosidic bond, this bond is called an α bond because the glycosidic bond to the anomeric carbon (C-1) on the other side of the ring as a substituent CH 2OH substituent (C 6 of the first glucose). If the glycosidic bond is on the same side of the CH2OH substituent, it is classified as a β bond (1 → 4) and the resulting molecule will be cellobiose. The anomeric carbon (C1) second glucose molecule, which is not involved in the glycosidic bond, can be in α- or β-anomeric form and form alpha maltose or beta maltose.

The isomer of maltose is isomaltose. It is similar to maltose, but instead of the α (1 → 4) linkage, it is in the α (1 → 6) position, the same type of linkage found in branches of glycogen and amylopectin.

Attributes :

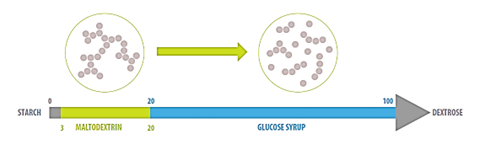

- Maltose is a component of malt, a substance that is obtained in the soaking and germination process of grain. It is also present in very different amounts in partially hydrolyzed starch products such as maltodextrin, glucose syrups, etc.

- Like glucose, maltose is a reducing sugar because the ring of one of the two glucose units can be opened to form a free aldehyde group. However, the other ring does not have such a characteristic due to the nature of the glycosidic bond.

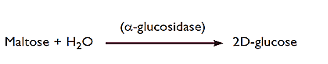

- Maltose can be broken down into glucose by the enzyme maltase, which catalyzes the hydrolysis of the glycosidic bond.

- Maltose in aqueous solution shows mutarotation, because the α- and β-isomers formed by the different conformations of the anomeric carbon have different specific rotations, and in aqueous solutions, the two forms form a dynamic equilibrium.

- It has a sweet taste, but depending on its concentration, it is only as sweet as 30 to 60% of sugar (sucrose). A 10% solution of maltose is 35% as sweet as sucrose.

- FDA considers maltose as a GRAS additive and therefore maltose can be used without any limitation except GMP’s.

Nutritional properties :

Maltose has 4 calories of energy per gram. Excessive consumption of sugars generally leads to several health problems such as obesity, high blood pressure and high blood glucose concentration. One of the disadvantages of maltose is its high glycemic index (GI = 105), which is one of the highest among common sugars.

Maltose syrup :

Maltose syrup refers to normal maltose syrup and high maltose syrup (HMCS) which is produced by enzymatic method. Maltose syrup and high maltose syrup is a food additive that is prepared by the acid-enzymatic conversion of starch, which is used as a sweetener and preservative in the food and beverage industry. It contains maltose, maltotriose and dextrin with a very small amount of dextrose, but the dominant part is maltose. Maltose is less sweet than high fructose corn syrup and contains little or no fructose. However, it is sweet enough to be useful as a sweetener in commercial food production. Although to be labeled “high” syrup must contain at least 50% maltose. Typically, it contains 40-50% maltose, although in some it reaches 70%. Using β-amylase or fungal alpha-amylase, it is possible to produce glucose syrups containing more than 50% maltose or even more than 70% maltose (extra high maltose syrup). These enzymes remove two glucose units, that is, one maltose molecule at a time, from the end of the starch molecule. This product has a long shelf life and improves the taste and texture of the product due to its properties such as sweet, delicate taste and stable nature at high temperature and acidic conditions.

Maltose can be found as a crystalline solid or syrup. Malt syrup is commercially available in 3 models based on dextrose equivalent (DE):

- High maltose syrup (DE 35-50, 45-60% maltose)

- Syrup with very high maltose (DE 45-60, 70-85% maltose)

- Syrup with high conversion (DE 60-70, 30-47% maltose)

Commercial Production :

Maltose syrup is produced commercially by the following process.

- Production of starch milk: starch materials such as rice or corn powder are mixed with water in a tank and then enzyme is added to them.

- Liquefaction: the mixture liquefies at high temperatures.

- Deproteinization: the starch milk is filtered to remove the remaining protein.

- Saccharification: liquefied material is added to the saccharification tank for reaction with β-amylase enzyme.

- Decolorization: Maltose syrup is decolorized with activated carbon.

- Filtration: activated carbon is removed through a filter press.

- Ion exchange: removal of cations and anions.

- Concentration and evaporation: the syrup is evaporated, cooled and stored in a vacuum.

Major producers of maltose in the world market are Cargill, Incorporated, Meelunie B.V., Nectafresh Agro Foods, and Austrade Inc.

Applications : Multipurpose properties of maltose and high maltose syrups :

Maltose syrup is added to several food products due to improved flavor, taste, structure and texture. At the same time, it provides resistance to color formation, moisture absorption and crystallization in final products such as hard candies. High maltose corn syrup is used as a substitute for normal glucose syrup in hard candy production at a given moisture level and temperature, the maltose solution has a lower viscosity than the glucose solution, but it still turns into a hard product. Maltose is also less humectant than glucose, so candy made with high-maltose syrup does not stick as easily as candy made with a standard glucose syrup. Maltose can be used as a substitute for sucrose in the formulation of baked products.

One of the health benefits of maltose is that adding it to various foods increases their shelf life. By inhibiting the fermentation and growth of bacteria, it preserves food. And therefore, it is widely used as a food preservative to maintain food quality and extend the shelf life of products. It provides exceptional stability and transparency to the final products. Maltose is commonly added to foods such as candies, pastries, jams, and jellies. Jellies, jams and syrups are often affected by microbial growths. However, adding maltose to these products can help control microbial growth. Adding maltose to such products can increase their volume, but at the same time reduce their sweetness. Maltose not only preserves the taste of foods, but also prevents them from losing their original color. The findings of studies in 2002 proved that the use of maltose is able to increase the production of saliva. In this way, maltose is an excellent remedy for dry mouth. Maltose lozenge in anhydrous crystalline form is used during this

treatment process. Maltose is added as an additive to spice mixes, mainly because of its antimicrobial properties. Because maltose has a low freezing point, high maltose corn syrup is useful in frozen desserts. It is also used in brewing, because it has a balanced fermentability, can be added at high concentrations to the wort kettle, increasing throughput, and reduces haze caused by varying malt quality. Cargill sells high maltose syrups with the main application of substituting malt in the manufacture of beer. In addition to being used in breweries, maltose syrup can be used in baking, liquid foods, chocolates, sweets, sauces, ice creams, etc. The thriving food and beverage industry owing to the growing consumer demands is significantly contributing to the industry growth. Increasing consumption of baked goods and confectionery in developed regions such as North America and Europe supports the growth of this industry.

Function of maltose in baked flour (bakery) products :

Maltose has several functions in the baking process:

- Sweetness: provides a sweet taste (although to a lesser extent than fructose, sucrose and glucose).

- Tenderizing: Maltose interferes with gluten network formation, protein coagulation and starch gelatinization, thus delaying structure formation.

- Moisture: It is the result of the hygroscopic nature of its structure.

- Shelf-life improvement: It can increase the shelf life of baked products by preventing moisture loss and staling.

- Browning: It helps in browning of baked goods via Maillard reaction as well as caramelization reactions. Maltose has the slowest browning rate of all common sugars.

- Leavening: only its crystalline form contributes to leavening.

- Nutrient for yeast fermentation: It helps with slow fermentation, aiding adequate gassing in the final proofing stages.

- Flavoring: Provides a distinct flavor (especially the syrup form of maltose).

Advantages of using maltose in baked products :

- Improves yeast fermentation, especially in proof stages

- Adds sheen to bagels when incorporated into the boiling water

- Gives a distinct flavor to baked bakery products.

- It produces a lower degree of browning than other common reducing sugars.

- The use of maltose in nougat creates a suitable texture and improves chewiness.

- Maltose creates appropriate viscosity and texture in biscuits and cookies.

- It feeds yeast and assists with baking and rising of bread.

Considerations when using maltose :

- Compared to sucrose, it has a milder sweetening effect, and therefore the dosage of maltose should be increased compared to sucrose.

- To replace granulated sugar with maltose syrup, divide the mass of sucrose by 0.80 and reduce the amount of liquid by the difference between the two.

Difference between maltose syrup and glucose syrup :

Compared to glucose syrup, the sugar components of maltose syrup refer to the percentage of sugar such as glucose, maltose, maltotriose, maltotatrose, etc., which is also called “constituent structure”. Different types of food with different specifications require different quality of syrup. Mastering the functional effects of syrup sugar components on foods and meeting technological needs in food production is mainly due to their characteristics.

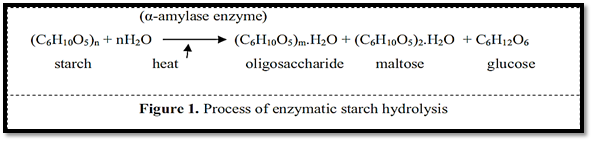

The constituents of sugar syrup are the products of starch hydrolysis and depend on the progress of hydrolysis. During liquefaction, starch is hydrolyzed to dextrin, and during saccharification, oligosaccharides (G7, G6, G5, G4, G3), maltose (G2) derived from dextrin (G8 and above) are hydrolyzed to glucose (G1). The molecular weight becomes smaller and smaller, the complex molecular structure changes to a simpler structure, and the properties of the sugar components change regularly.

Syrup characteristics influenced by hydrolysis :

Viscosity: decreases with the degree of hydrolysis.

Thermal stability: increases with the degree of hydrolysis.

Resistance to crystalinity: decreases with the degree of hydrolysis.

Solubility: increases with the degree of hydrolysis.

Osmotic pressure: increases with the degree of hydrolysis.

Moisture activity: decreases with the degree of hydrolysis.

Browning reaction: increases with the degree of hydrolysis.

The ability to create aroma and flavor) perfuming ability ) : decreases with the degree of hydrolysis.

Fermentation capacity: increases with the degree of hydrolysis.

- Different production process: Glucose syrup is produced by using hydrochloric acid or sulfuric acid as a catalyst; maltose syrup and oligosaccharide syrup are produced by using an enzyme preparation as a biocatalyst. Whether it is syrup using acid or enzymatic process, the production process uses acid or enzyme preparations in different varieties, dosages, production conditions and reaction time, and the products produced are different. In other words, the production process of various syrups is different.

- Maltose syrup compared to glucose syrup has different sugar compounds and the resulting syrup has different physical and chemical properties. The sugar component of the syrup not only directly determines the amount of DE (i.e., the amount of reducing sugar), but more importantly, it determines the sweetness, viscosity, solubility, sugar temperature, browning reaction, aroma retention, anti-crystallization and absorption temperature of the syrup. A wide range of physicochemical properties such as heat preservation and fermentability). The biggest difference between glucose syrup, maltose syrup and oligosaccharides is not in their respective production processes. In fact, with the development of new types of enzyme production methods and the improvement of applied technology, it is now possible to produce many syrups with the enzyme process and achieve various quality indicators. The biggest and most fundamental difference between maltose syrup and glucose syrup is that they have different syrup sugar compositions. The sugar component of glucose syrup is generally rich in glucose, and components such as glucose (G1), maltose (G2), maltotriose (G3) and maltotetraose (G4) are reduced in a certain proportion. The sugar component of maltose syrup is mainly maltose with the least amount of glucose, and the total content of G3+G4+G5 is more. The sugar components of these syrups form the physicochemical properties of syrups and make them widely available in the production of food such as confectionery, biscuits and sweets. Another example, the DE value of syrup is 42, the composition of acidic syrup: G1: 19.3%, G2: 14.3%, G3: 11.8%, G4 and above in total 54.6%. Composition of enzyme syrup: G1: 0.8%, G2: 48.2%, G3: 17.6%, and and G4 and above totaled 33.4%. The use of these two syrups is different. The first one can only produce normal hard candy, but its shelf life is not long. The latter can be used to produce high-quality confectionery, which can also be used to produce high-quality crispy biscuits. The structure of the components of the syrup determines the properties and consumption value of the syrup, and the comprehensive use of the properties of the syrup creates excellent quality and brand characteristics of different foods. In the hygroscopicity (water vapor absorption) of sugar, usually G3>G4>G5=G7>G1>G2, maltotriose has the highest moisture absorption and maltose has the lowest. In moisturizing oligosaccharides (water retention) (G3-G7), moisture retention is relatively high and G2>G1. Glucose is very absorbent of steam and moisture and has a poor water holding capacity. In the confectionery industry, we often find that candy with high glucose content will be sticky, so-called “confectionery hairpin”.

Increasing consumer health awareness and more demand for high maltose syrups :

In recent years, HMCS has seen an increase in use as a food additive due to the negative reputation of HFCS, as well as the absence of fructose, which is the source of the concern about the health effects of high fructose corn syrup. In addition, maltose syrups Corn-based syrups are gluten-free, thus meeting the demand for gluten-free products. But some syrups made from wheat or barley may contain small amounts of gluten, and it is not known whether this can have significant effects in celiac disease. Therefore, in cases where there is a sensitivity to the absence of gluten, especially in the case of specific food products for celiac patients, it is preferable to use corn maltose syrup. It is recommended that people who take care of their health consumes sugars in moderation. What is notable about maltose is that it contains glucose, which gives this sugar a high glycemic index (GI).

The importance of sweeteners in life :

Carbohydrate-based foods are converted into sugar molecules in the human body. Therefore, excessive consumption of these products exposes people to the risk of diseases such as heart diseases, diabetes, etc. Added sugars in processed products such as soft drinks, packaged fruit juices, cereals, biscuits, cookies, cakes, candies, bread, processed meats, etc. lead to adverse health outcomes including obesity and diabetes. High calorie intake from added sugar is associated with a significantly increased risk of cardiovascular disease (CVD) mortality. All these health consequences and increasing consumer awareness direct consumers’ interest towards choosing a healthy lifestyle with lower sugar and low-calorie consumption and more attention for nutritious and natural product options. This growing demand for natural and healthier ingredients in the food industry has led to an increase in demand for high maltose syrups, especially those produced from corn or other natural sources. Also, increasing desire and demand for natural and gluten-free food products among consumers with increasing health awareness will help the growth of this sector. In recent years, high maltose corn syrups have seen an increase in demand as a food additive due to the negative reputation of high fructose corn syrups that have adverse health effects. Maltose is safer than fructose and galactose. Additionally, the cohesive properties of maltose may increase the product’s demand in the pharmaceutical industry as an alternative to chemically produced sugar. Other factors such as growing demand for ready-to-drink beverages, confectionery and baked goods, escalating disposable incomes and rising living standards, increased R&D activities, and new product launches are expected to further boost the industry growth over the forecast period. These are the new emerging sectors where these High Maltose Syrup manufacturers and Suppliers will have the expected growth.

Prepared and written by: Mandana Alipour

Director of Research and Development of Golshad Grain Refinery

The use of the contents of this article is permitted by mentioning the source.

انواع طبقه بندی مالتوز

بر اساس منبع نشاسته

⦁ منابع طبیعی

⦁ ذرت

⦁ سیب زمینی شیرین

⦁ جو مومی

⦁ نشاسته برنج

⦁ منابع شیمیایی و آنزیمی

⦁ β-amylase

⦁ fungal α-amylase

بر اساس استفاده نهایی ⦁ محصولات آردی و نانوایی

⦁ صنعت تخیمر و آبجو سازی

⦁ صنعت نوشیدنیهای بدون الکل و نوشابه

⦁ دسرهای منجمد

بر اساس غلظت ⦁ شربت با غلظت بالای مالتوز

⦁ شربت با غلظت بسیار بالای مالتوز

:References

⦁ Belitz, H.-D .; Grosch, Werner; Schieberle, Peter (2009-01-15). ⦁ Food Chemistry (in English). Springer Science & Business Media. p. 863. ⦁ ISBN ⦁ 9783540699330.

⦁ Spillane, WJ (2006-07-17). ⦁ Optimizing Sweet Taste in Foods (in English). Woodhead Publishing. p. 271. ⦁ ISBN ⦁ 9781845691646.

⦁ “Substances Added To Food (Formerly EAFUS)”. Cfsanappsexternal.Fda.Gov, 2020, ⦁ https://www.cfsanappsexternal.fda.gov/scripts/fdcc/index.cfm?set=FoodSubstances⦁ &⦁ id=MALTOSE. Accessed 9 Oct 2020.

⦁ Figoni, P. How Baking Works: Exploring The Fundamentals Of Baking Science. 2nd ed., John Wiley & Sons, Inc., 2008.

⦁ Qi, Xin, and Richard F. Tester. “Lactose, Maltose, and Sucrose in Health and Disease.” Molecular Nutrition & Food Research 64.8 (2020): 1901082.

⦁ “Maltose Syrup Manufacturing Process Solution-Maltose Syrup Processing Technology Business Plan”. Syrupmachinery.Com, 2020, https://www.syrupmachinery.com/solutions/#:~:text=Maltose%20syrup%20process%20machine%20technololurry%20unit%20during%20the,transported%20to%20next%20work%20section. Accessed 9 Oct 2020.

⦁ “Substances Added To Food (Formerly EAFUS)”. Cfsanappsexternal.Fda.Gov, 2020, https://www.cfsanappsexternal.fda.gov/scripts/fdcc/index.cfm?set=FoodSubstances&id=MALTOSE. Accessed 9 Oct 2020.

⦁ “Maltose – Substance Information – ECHA”. Echa.Europa.Eu, 2020, ⦁ https://echa.europa.eu/nl/substance-information/-/substanceinfo/100.000.651. Accessed 9 Oct 2020.

⦁ Hull, P. (2010). Glucose syrups: Technology and Application. Wiley Blackwell Publication.

⦁ Tomasik, P., Horton D.(2012).Enzymatic Conversions of starch. Adv. Carbohydrte. Chem. Biochem., 68,59-436.